Maxim DL did not work very well with the Audine as a guide scope - when I would click back to full frame, the driver would crash. Further, Maxim does not seem to use real time threading as while it downloads the image via USB of any camera I have, Maxim freezes! So I revived code I had for my home brewed CCD image processing, added Audine code off the web, nursed it a bit, and voila 3 days later an automatic Audine guide handler linked in with my own dome controller software. When ASCOM slews or pulses the scope, or when the Audine cooling temperature changes sufficiently, it automatically reacquires a target and a dark frame. Fire and forget, all night long! The Audine is a terrific and sensitive camera, I couldn't replace it with an expensive guider.

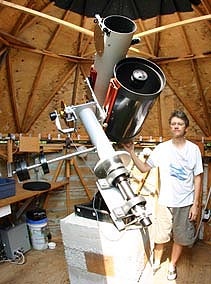

Came time to purchase a 0.5 meter class, I settled for the 0.35 m (14") Celestron OTA. 2 month after purchase, Celestron released the edgeHD, with 3 times wider flatter focal plane. No matter, I'll mostly be imaging with fastar/hyperstar which replaces the front mirror with a lens assembly for F/2 ultra fast imaging.

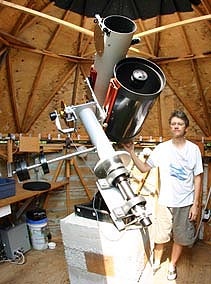

Most of the previous equipment was re-used, described here. I designed & machined the extended head German mount (obviates flipping scopes crossing meridian). The 250 lbs mount is rock steady, even while touching the scopes. I reused the lower section of the previous mount as it was adequate. My work horse 8" newtonian serves as guide scope. The entire observatory is remotely controlled: see Movie.

Mount specifications:

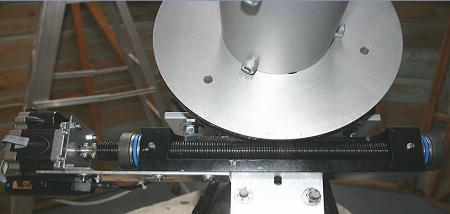

- Polar shaft: 3" steel, 0.5" wall, 12" RA gear (1" ACME screw).

- Declination shaft: 2" solid stainless, Byers 9.7" dec gear.

- Thru polar shaft cabling, all equipment on mount.

- Design weight/balance, cost analysis & drawings here

A fish eye view into the dome below (hyperstar + QSI583ws CCD on C14 corrector):

Astronomy: equipment 1

Updated: Mar 2016

Click here to better view this site

The Hyperstar comes into its own with the QSI 583ws CCD camera with internal colour filter wheel installed in early 2010. At F/1.9, this system is fast! The Orion nebula saturates in 10 seconds.

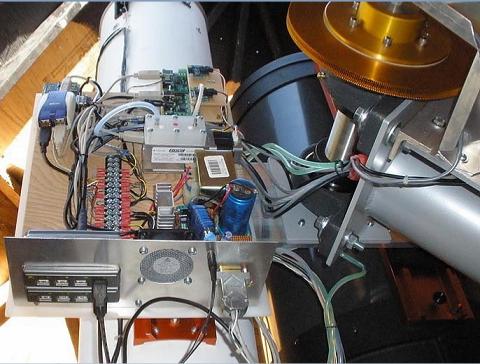

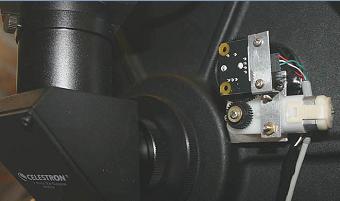

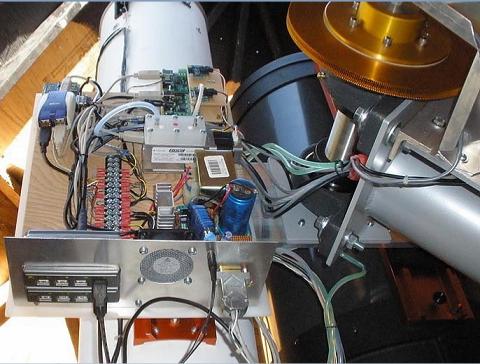

Phidgets are extensively used to facilitate control of the dome, mount and scopes. All components are USB (C14 ASCOM focus motor and equipment bay shown in photos):

- Aperture panel actuators (qty 2 on C14, 1 on guide scope)

- RA + Dec intelligent direct drive motors

- RA + Dec 17 bit absolute encoders (FPGA)

- Vacuum pump for CCD (no frost, controlled to 0.1 psi)

- Cooling fluid pump (CCD cameras)

- Audine CCD control

- Audine thermo-electric (controlled to 0.1 deg)

- QSI 583ws CCD camera

- Orion Starshoot CCD

- Dome absolute position (bar code) and magnetometer

- Dome relative position/velocity (encoder)

- C14 Focus motor encoder (80 pulses/turn)

- C14 & guide scope focus motors (PWM speed control)

- In dome IR pan/tilt web cam

- In dome IR lamp

- Dome and slit actuation

- Slit upper/lower opening sensing + battery voltage and current

- Misc control (Dome cooling fans, flood lighting (CCD flats), etc)

- Misc I/Os: Dome temperature, vacuum pressure, spares

Work (of note) carried out:

- The C14 corrector was heated to 300 F (164 C) in an oven for 30 minutes to liberate the loctite on the baffle tube so the Hyperstar conversion kit could be installed.

- Tested Quatech's USBN-500W USB wireless & Icron Ranger 2104 PnP routers. The Quatech failed on the cameras, but the Icron didn't. The observatory runs from the house PC. The Icron is via a buried CAT6 cable. An Icron wireless WiRanger was tested as insufficient (connectivity failures). The Quatech was re-used for the dome/slit battery powered USB servicing in ad-Hoc wireless with local bridge onto wired ethernet back to the house, but finally replaced with a Phidgets SBC2 [single board computer] due to connectivity issues.

Issues and way forward:

- RA worm has 60 arc-sec PE, brought down to 10 with sine + high order PEC: see here - note small dents in worm caused spikes. Problem due to low quality end bearings & collars. Replaced with German bearings and machined threaded locking collars (result here). Will fabricate new worm mount and support using bushings and tighter tolerances in summer '11.

- Design and construction of fiber optic coupled spectrometer

A Davis weather station and sky quality meter SQM-LE (ethernet) share the mast off the Dome. The SQM monitors the quality of the sky background. Installed inside a weather, heat and light proof enclosure, complete with power supplies and coax ethernet, protection from electrical storms and auto snow melt. Readings logged here. The perl script also extract data from the clear sky clock and merges it with the SQM data.

Work on 1.5 meter wide twin dome shutters began late winter 2010. They're required for the large C14 and N8 German mounted pair.

Above: the shutter structure was most elastic and weak until the cross braces were added, when it became astoundingly stiff - the shutters can support over 300 pounds each despite their 20 pound weight and this before aluminum skinning. It must be so because of snow accumulation over their combined 6 foot span.

At right, the shutters are shown mounted on the framework and rails before painting and aluminum skinning in their fully open position. The entire assembly takes the better part of a two car garage!

Below, the tractor was used to lift the shutters, a task that proved daunting because of the observatory height. It would have been quite impossible without the tractor. Sadly, the right shutter lower aluminum panel was wrinkled during the lift. The job completed below!

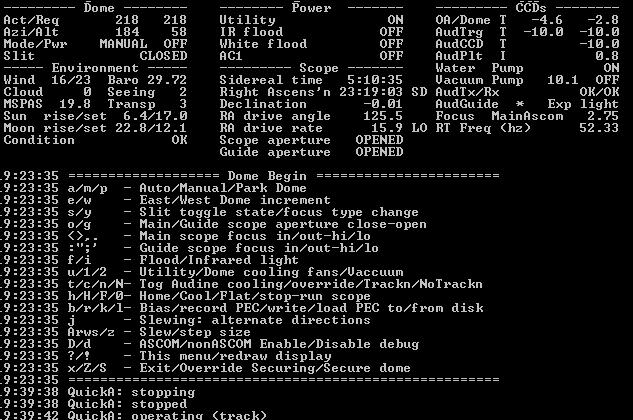

My own dome controller began in 1996, so it's keyboard input only, but does the job. It's linked via ASCOM for the mount, C14 focuser and dome. One day I might code a GUI layer.

A setting on the dome controller moves the scope and dome so that the flats white board is properly oriented for the C14, and turns on a DIY diffused white LED light source. It is mounted on the QSI CCD camera back and centered on the C14 optical axis. Here the dome infrared are on to see the flats panel and the scopes for reference (three left most photos below). Flats are a snap! However I later replaced it with an A2 size electro-luminescent panel purchased from ZLUX in Montreal (rightmost photo below).

It got to be trouble to have the rotating dome powered only when at the park position, and so I installed a 12V battery system with wireless Phidgets SBC2 (single board computer) servicing sonars, A/Ds and a relay unit. The doors can be opened/closed at any dome azimuth, and the top and bottom door slit opening are measured to sense a disastrous jam condition. Battery voltage and current are sensed to prevent depletion. The sonar were mounted in an ABS tube as they could only read down to 15 cm. A foam ring near the sensor prevents local reflections with the tube otherwise acting as a wave guide. But due to connectivity issues (serial/USB over wireless with Quatech), I had to drop these and make sensors out of 4$ tape measure (used for the spring return) and 10:1 pots I had lying around when I switched to the SBC2. However when temperature was hovering around freezing, dew would freeze on the tape and jam them, so I purchased and modified spring loaded string clothes line units replacing the string with nylon fishing wire! Commercial grade string pots are very expensive. In 2016, I switched to using two laser rangers (see here).

The dome wood drive guide channel had eroded over the years so it was replaced with a laser cut 1/8" thick steel base plate, permanently. Takes the better part of a two car garage of course.

The four dome drive motors were supported by wood structures prone to flexing over time; steel replacements were designed and installed. Much better! New panelling too.